STAINLESS STEEL INTRODUCTION

STAINLESS STEEL INTRODUCTION

Definition:

Steel containing more than 12% chromium that can resist chemical attacks.

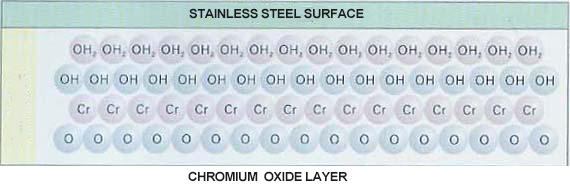

Principle::

Stainless steel does not mean it won't rust, but rather it is resistant to rusting. The principle

involves the addition of chromium, which forms a dense chromium oxide layer on the surface of

the steel, effectively preventing further contact between the steel and air. This inhibits the entry

of oxygen from the air into the steel, thereby preventing rusting.

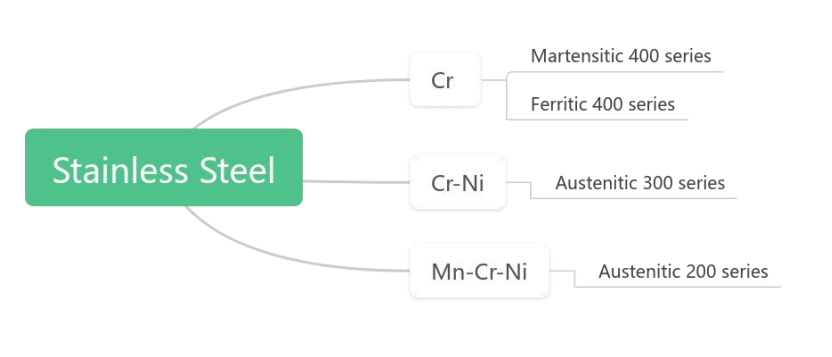

Chinese National Standards (CNS), Japanese Industrial Standards (JIS), and the American Iron and

Steel Institute (AISI) use three-digit numbers to represent different types of stainless steel, widely

referenced in the industry. The 200 series refers to chromium-nickel-manganese austenitic

stainless steel, while the 400 series refers to ferritic stainless steel (commonly known as stainless

iron), including martensitic and ferritic elements.

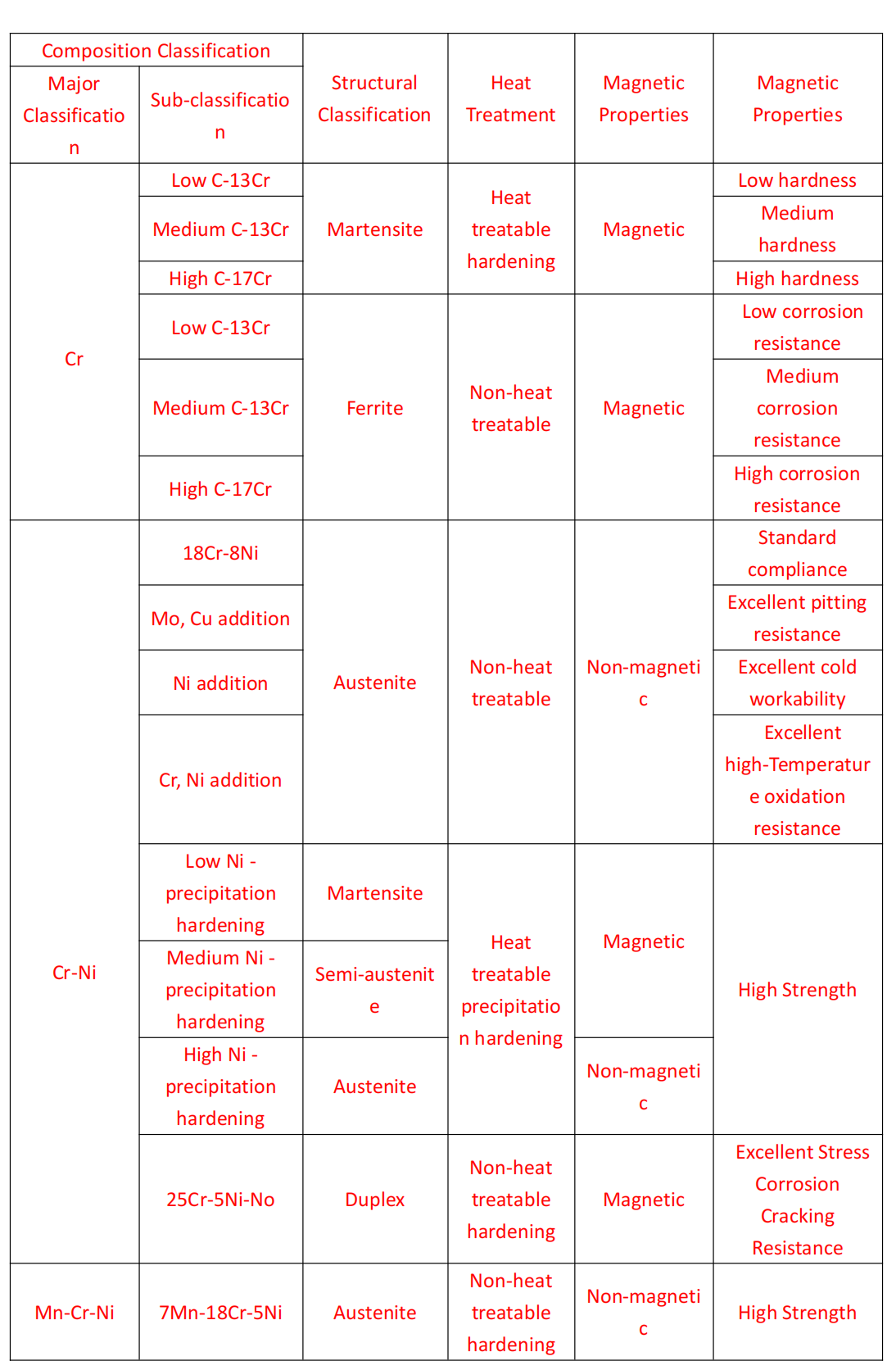

Additionally, classification can be based on composition, magnetism, ability to undergo heat

treatment hardening, and steel grade numbers, as shown in the table below::

Magnetism:

All austenitic stainless steel balls are typically non-magnetic; however, some magnetism may be

apparent after cold working. Standard: ISO3506 GB/T3098.6 Various materials' ability to be

magnetized. Applicable to stainless steel. Complete non-magnetism is only possible under

vacuum conditions. The measurement of the magnetic permeability of a material in a magnetic

field is relative to the material's magnetic permeability μr in a vacuum. If μr is close to 1, the

material has low magnetic permeability. For example: A2: μr ? 1.8, A4: μr ? 1.015, A4L μr ? 1.005, F1: μr ? 5.

The strength of magnetism is closely related to the alloy composition of the steel. The following is

the formula for calculating magnetism (smaller values indicate lower magnetism):

MD30 = 551-462×(C+N)-9.2×Si-8.1×Mn-13.7×Cr-29×(Ni+Cu)-18.5×Mo

Q&A:

Should I choose A2 or A4 stainless steel balls?

Answer: A) Prioritize choosing A2 (commonly known as 304) stainless steel balls, as they

generally satisfy most usage environments.

B) In environments with higher corrosive requirements, such as petrochemicals, chemicals, nuclear power, and coastal areas, consider using A4 (commonly known as 316)

stainless steel balls.

浙公網(wǎng)安備 33060402000318號(hào)

浙公網(wǎng)安備 33060402000318號(hào)